800.605.1859 - FREE SHIPPING ON MOST ITEMS OVER $99.00

Accessories

lighting

Designers

- ACHILLE CASTIGLIONI

- ALBERTO MEDA

- ALESSANDRO MENDINI

- ALEXANDER GIRARD

- ALFREDO HABERLI

- ALVAR AALTO

- ANNA CASTELLI FERRIERI

- ANTONIO CITTERIO

- ARNE JACOBSEN

- BARBER & OSGERBY

- CARLO ALESSI

- CARLO MOLLINO

- CHARLES & RAY EAMES

- CHARLOTTE PERRIAND

- EERO SAARINEN

- EILEEN GRAY

- ENZO MARI

- ERNESTO GISMONDI

- ETTORE SOTTSASS

- ACHILLE CASTIGLIONI

- ALBERTO MEDA

- ALESSANDRO MENDINI

- ALEXANDER GIRARD

- ALFREDO HABERLI

- ALVAR AALTO

- ANNA CASTELLI FERRIERI

- ANTONIO CITTERIO

- ARNE JACOBSEN

- BARBER & OSGERBY

- CARLO ALESSI

- CARLO MOLLINO

- CHARLES & RAY EAMES

- CHARLOTTE PERRIAND

- EERO SAARINEN

- EILEEN GRAY

- ENZO MARI

- ERNESTO GISMONDI

- ETTORE SOTTSASS

sale

Save 15% + Free Shipping -Now Thru March 19th

Save 20% + Free Shipping -Now Thru March 19th

Save 15% + Free Shipping -Now Thru March 19th

Warehouse Sale up - Up to 70% off

Save 15% + Free Shipping -Now Thru March 19th

Save 20% + Free Shipping -Now Thru March 26th

Save 10%+ Free Shipping - Now until March 29th

Save 15% + Free Shipping -Now Thru March 31th

Save 20% + Free Shipping -Now Thru March 5th

Save 15% + Free Shipping -Now Thru March 19th

Save 15% + Free Shipping -Now Thru March 19th

Save 15% + Free Shipping -Now Thru March 31th

Save 15% + Free Shipping -Now Thru March 19th

Save 15% + Free Shipping -Now Thru March 19th

Save 25% + Free Shipping -Now Thru March 19th

Save 15% + Free Shipping -Now Thru March 19th

In-Stock Items

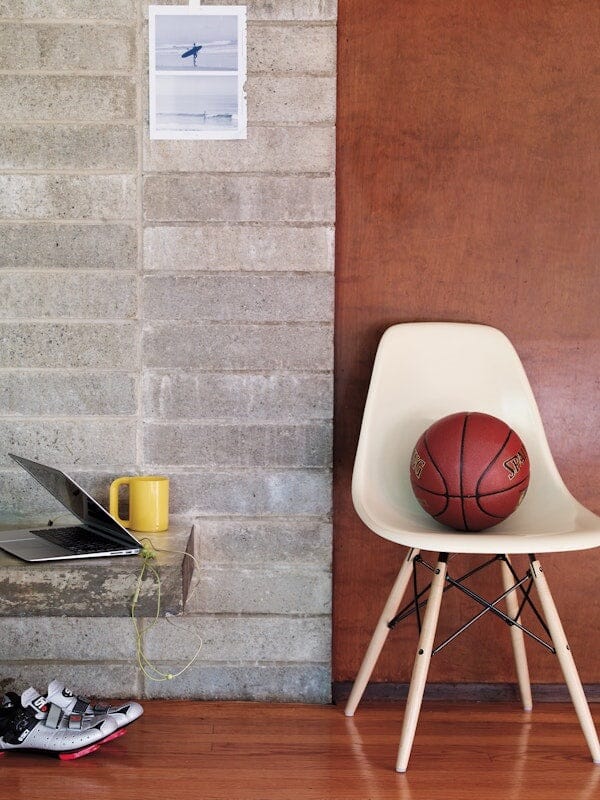

Eames Molded Fiberglass Side Chair with Wood Dowel Base

*****USUALLY SHIPS IN 120-130 BUSINESS DAYS*****

All Eames Molded Fiberglass Shells are on Hold until Further Notice

Design Charles & Ray Eames, 1948

Molded fiberglass, metal frame

Made by Herman Miller®

Designers: Charles and Ray Eames With the Eames Molded Fiberglass Side Chair, the Eameses created a universal response to what everyone wants from a chair: a simple, gracious form that fits any body and every place. Thanks to a new, proprietary process of producing fiberglass-reinforced plastic, Herman Miller is once again able to produce the original 1950 Eames Molded Fiberglass Side Chair safely. The Molded Fiberglass Side Chair is available in eight archival colors as well as numerous upholstery and base options, making it an ideal dining chair option for both formal and informal spaces alike.

A Finer Fiberglass

Thanks to a new, proprietary process of producing fiberglass-reinforced plastic, Herman Miller is once again able to produce the original 1950 Eames Molded Fiberglass Chair safely by means of a less volatile, monomer-free "dry bind" process. Like the original shell chairs, our new fiberglass finish has the same covetable surface variation and telltale fiberglass striation that have attracted avid vintage collectors for decades.

Limitless Possibility

The Molded Fiberglass Side Chair is available in eight archival colors, numerous upholstery options, and can be configured with a choice of wire, dowel leg, stacking, and 4-leg bases.

Take Back Program

Like the countless fiberglass shells that have been beloved by avid Eames collectors and design enthusiasts for years, we expect our newly formulated Eames Molded Fiberglass Side Chair to endure for generations to come. However, in the off chance your Molded Fiberglass Side Chair is compromised, Herman Miller's Take Back program offers an environmentally sound means for recycling it.

Tailor Made

An array of trim, finely tailored Hopsak fabrics designed by Alexander Girard, Herman Miller's Textile Director from 1952 to 1973, round out the collection of shell customization options, fully restoring the integrity of the original 1953 shell chair offerings. Reproduced as faithfully as possible to Girard's original weave and color selections, the textile boasts one enhancement: it now uses more sustainable constructions and materials such as antimony-free polyester.

Tailor Made

An array of trim, finely tailored Hopsak fabrics designed by Alexander Girard, Herman Miller's Textile Director from 1952 to 1973, round out the collection of shell customization options, fully restoring the integrity of the original 1953 shell chair offerings. Reproduced as faithfully as possible to Girard's original weave and color selections, the textile boasts one enhancement: it now uses more sustainable constructions and materials such as antimony-free polyester.

A "Preform" that Performs

To create preforms for the new Eames Molded Fiberglass Arm and Side Chairs, a "dry binder process" is used. With this technique, fiberglass strands, some of which melt at a lower temperature, are blown by a robot onto a screen in the shape of the chair shell. Heat is then applied, and enough strands melt so that the preform's shape remains intact, avoiding the harmful "wet glue" process used in traditional fiberglass fabrication.

A Greener Resin

By employing technology used mainly in the automotive and manufacturing industries, this new fiberglass resin boasts many environmental improvements. Monomer-free and processed without VOC (volatile organic compounds) or HAP (hazardous air pollutants) emissions, these resins eliminate the need for thermal oxidizers. Compared to the fiberglass resins used in the Eameses' original design, the new resin results in a safer work environment for employees.

General Dimensions

- H:31.75"

- H:18.5"

- W:18.75"

- D:21.75"

Eames Molded Fiberglass Side Chair with Wood Dowel Base

*****USUALLY SHIPS IN 120-130 BUSINESS DAYS*****

All Eames Molded Fiberglass Shells are on Hold until Further Notice

Design Charles & Ray Eames, 1948

Molded fiberglass, metal frame

Made by Herman Miller®

Designers: Charles and Ray Eames With the Eames Molded Fiberglass Side Chair, the Eameses created a universal response to what everyone wants from a chair: a simple, gracious form that fits any body and every place. Thanks to a new, proprietary process of producing fiberglass-reinforced plastic, Herman Miller is once again able to produce the original 1950 Eames Molded Fiberglass Side Chair safely. The Molded Fiberglass Side Chair is available in eight archival colors as well as numerous upholstery and base options, making it an ideal dining chair option for both formal and informal spaces alike.

A Finer Fiberglass

Thanks to a new, proprietary process of producing fiberglass-reinforced plastic, Herman Miller is once again able to produce the original 1950 Eames Molded Fiberglass Chair safely by means of a less volatile, monomer-free "dry bind" process. Like the original shell chairs, our new fiberglass finish has the same covetable surface variation and telltale fiberglass striation that have attracted avid vintage collectors for decades.

Limitless Possibility

The Molded Fiberglass Side Chair is available in eight archival colors, numerous upholstery options, and can be configured with a choice of wire, dowel leg, stacking, and 4-leg bases.

Take Back Program

Like the countless fiberglass shells that have been beloved by avid Eames collectors and design enthusiasts for years, we expect our newly formulated Eames Molded Fiberglass Side Chair to endure for generations to come. However, in the off chance your Molded Fiberglass Side Chair is compromised, Herman Miller's Take Back program offers an environmentally sound means for recycling it.

Tailor Made

An array of trim, finely tailored Hopsak fabrics designed by Alexander Girard, Herman Miller's Textile Director from 1952 to 1973, round out the collection of shell customization options, fully restoring the integrity of the original 1953 shell chair offerings. Reproduced as faithfully as possible to Girard's original weave and color selections, the textile boasts one enhancement: it now uses more sustainable constructions and materials such as antimony-free polyester.

Tailor Made

An array of trim, finely tailored Hopsak fabrics designed by Alexander Girard, Herman Miller's Textile Director from 1952 to 1973, round out the collection of shell customization options, fully restoring the integrity of the original 1953 shell chair offerings. Reproduced as faithfully as possible to Girard's original weave and color selections, the textile boasts one enhancement: it now uses more sustainable constructions and materials such as antimony-free polyester.

A "Preform" that Performs

To create preforms for the new Eames Molded Fiberglass Arm and Side Chairs, a "dry binder process" is used. With this technique, fiberglass strands, some of which melt at a lower temperature, are blown by a robot onto a screen in the shape of the chair shell. Heat is then applied, and enough strands melt so that the preform's shape remains intact, avoiding the harmful "wet glue" process used in traditional fiberglass fabrication.

A Greener Resin

By employing technology used mainly in the automotive and manufacturing industries, this new fiberglass resin boasts many environmental improvements. Monomer-free and processed without VOC (volatile organic compounds) or HAP (hazardous air pollutants) emissions, these resins eliminate the need for thermal oxidizers. Compared to the fiberglass resins used in the Eameses' original design, the new resin results in a safer work environment for employees.

General Dimensions

- H:31.75"

- H:18.5"

- W:18.75"

- D:21.75"

You may also like

Subscribe

Sign up to get the latest on sales, new releases and more …